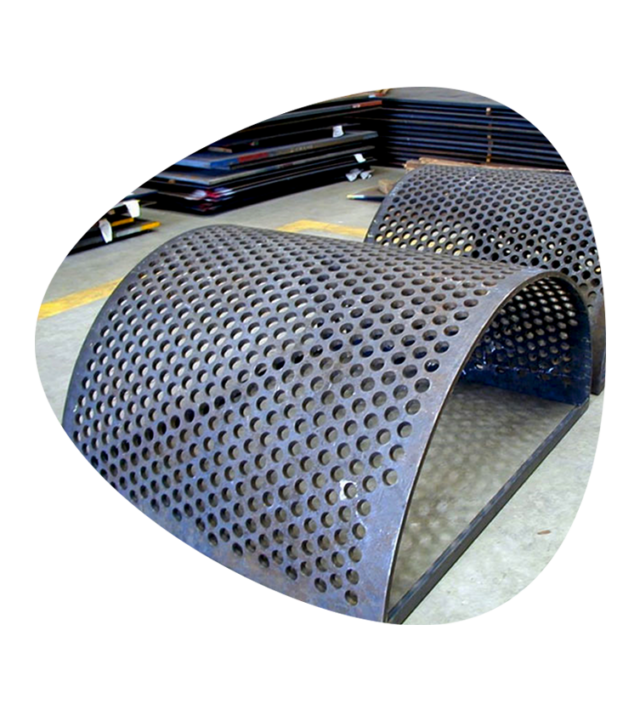

Grizzly Screen

The Max Steel engineering team works closely with our customers to provide completely custom replacement grizzly screens designed to handle our customer’s exact material and environmental conditions using original Hardox Wear Plates and certified fabrication processes to ensure a high quality .

With an abrasion-resistant and high-impact-resistant steel like Hardox® in your grizzly screens, you can reduce breakage and extend service life – even to double the service life.

Our service commitments start from client engagement and onsite inspection. Our technical team will accurately take measurements and provide GA drawings for client approval. The fabrication team will take over with the final product going through rigorous quality checks before delivery to client. We are also able to offer installation services.

All products supplied are validated with our QC team and are covered against fabrication defects. Mill Test Certificates, Welding Tests, and other applicable certification will also be provided.

Liners

We pride ourselves on being able to provide total solutions on most projects. We want to maintain a full complement of fabrication equipment and can handle complex jobs, including hoppers, troughs, and sumps in standard and special sizes.

Whether it’s a custom or large production run, we’re committed to meeting your fabrication needs.

Chutes are used to transport material from one process step to another in mining operations. When material is fed into a process or discharged from it, chutes collect, convey and prepare the material flow for the following processing phase. Chutes are used with crushers, feeders, conveyors, stackers, and grinding mills.

Customized chutes for mining operations:-

- Conveyor transfer chutes

- Crusher feed and discharge chutes

- Feeder discharge chutes

- Tripper chutes

- Stacker chutes

- Mill feed and discharge chutes